Furon® HPVM, 2-Way (Mini) Valve Cycling Test

An accelerated life test was conducted on Furon HPVM 2-way (mini) valves which were subjected to 1,000,000 cycles.

Accelerated Life Test Method

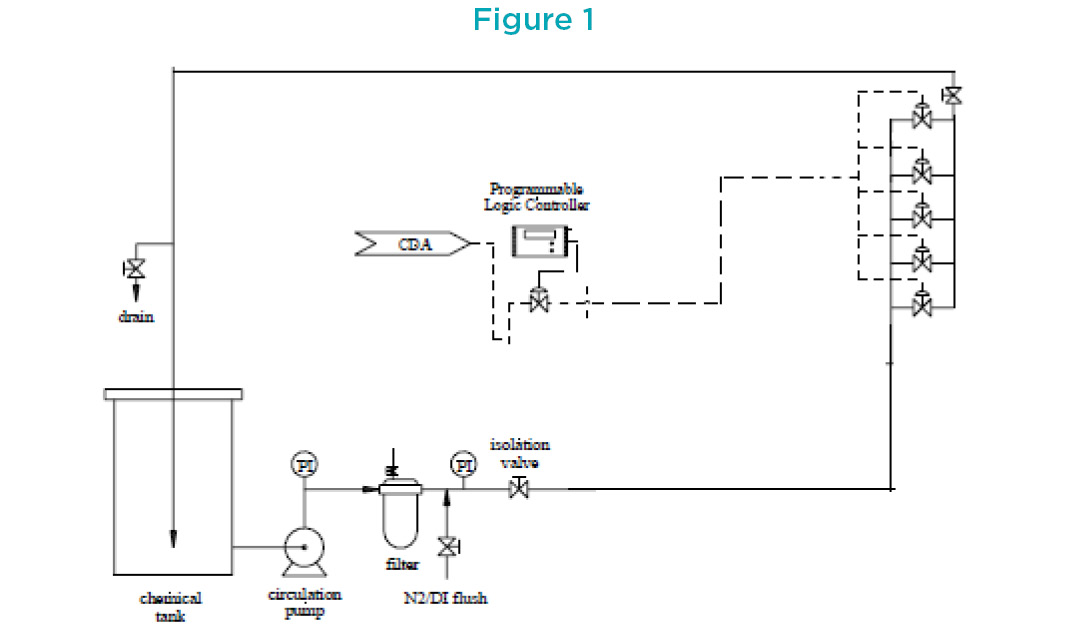

Five Furon HPVM, 2-way mini valves were assembled in a manifold set (Figure 1). Each valve was cycled 3 seconds open and 3 seconds closed at room temperature with an actuator pressure of 70 psig (4.8 bar). The pressure of the deionized (DI) water running through the valve was set at 80 psig (5.5 bar). At regular cycle intervals the valves were removed from the manifold and examined to ensure they retained pressure capabilities and performance integrity.

The data provided here was obtained under defined test conditions. Saint-Gobain Performance plastics makes no specific claims about the performance of the component with other test parameters or provides any warranties.

Throughout the test the valves were evaluated for cracking pressure and internal leakage. Internal leak testing was conducted by positioning the valves in a vertical orientation with the test ports down. Degassed ultrapure water then flowed upward through the valves. The valves were opened and closed several times and agitated to evacuate air bubbles. The valves were then left closed. The downward facing test ports were drained of water and pressurized with clean dry air CDA. The upward facing ports were plumbed to a bubble trap to monitor any air leaks past the seat. This procedure was repeated for both the inlet and outlet ports of each valve in agreement with the pressure requirement of 100 psi for the forward pressure and 80 psi for the back pressure. Crack pressure testing was conducted by plumbing a variable pressure CDA supply to the test port of a closed valve, and a pressure gage to the other port. CDA pressure was slowly increased to a maximum of 100 psi, or until the pressure gage at the other port increased, indicating a bypass. The CDA pressure required to cause the bypass was then recorded.

Summary

Furon HPVM2 (mini) valves were successfully exposed to 1,000,000 cycles in an accelerated life test without suffering any major performance loss. All tested parameters completed at fixed intervals were acceptable and in line with the valve specification. The valves remained on the test bench until the bench was required for another testing. At that time the cycle count was 2,300,000 without any record of performance loss.